Ključna uloga pakiranja pizze u zadovoljstvu kupaca

U konkurentnom svijetu dostave pizze, skromno kutija za pizzu igra mnogo važniju ulogu nego što većina ljudi misli. Iznad svega što je samo spremnik, kutija za pizzu služi kao ključni čuvar kvalitete hrane, održavanja temperature i ukupnog iskustva kupca. Od lokalnih pizzerija do velikih lanaca restorana, odabir odgovarajuće kutije za pizzu može biti razlika između dostave savršene pizze i razočaranja vrednih kupaca.

Svaki dan milijuni pizz putuju od pećnica do kućnih vrata, a svaka takva vožnja donosi jedinstvene izazove. Prava kutija za pizzu djeluje kao zaštitni štit, održavajući savršenu ravnotežu topline, vlage i strukturne čvrstoće. Ovaj ključni dio pakirne tehnologije znatno se razvio tijekom desetljeća inovacija u dostavi pizze, uključujući specijalizirane materijale i dizajnerske značajke koje doprinose boljem gastronomskom iskustvu.

Razumijevanje inženjerstva kutije za pizzu

Znanost o materijalima iza kvalitetnih kutija za pizzu

Suvremene kutije za pizzu su čuda materijalnog inženjerstva, obično izrađene od valjanog kartona koji nudi optimalna termička svojstva. Valovi između slojeva stvaraju džepove zraka koji pružaju prirodnu izolaciju, pomažući u održavanju idealne temperature tijekom dostave. Kutije visoke kvalitete koriste materijale prihvatljive za hranu koji otporni na upijanje vlage, a istovremeno omogućuju dovoljno ventilacije kako bi se spriječilo omekšavanje.

Debljina samog kartona je ključna, pri čemu premium kutije imaju više ECT (Edge Crush Test) ocjene koje osiguravaju stabilnost i čvrstoću pri slaganju. Ovo postaje posebno važno za poduzeća koja istovremeno obrađuju više dostava, jer strukturni integritet mora biti održan tijekom cijelog putovanja.

Dizajnerski elementi koji su važni

Nadređeni dizajn kutije za pizzu uključuje različite elemente koji zajedno štite proizvod. Rupice za ventilaciju, strategijski smještene po cijeloj kutiji, omogućuju ispuštanje pare bez kompromitiranja zadržavanja topline. Ova delikatna ravnoteža sprječava nakupljanje vlage koja bi mogla učiniti koricu mekom, istovremeno držeći pizzu dovoljno toplo za zadovoljstvo kupca.

Unutarnja obrada površine kvalitetnih kutija za pizzu često uključuje posebne premaze koji otporni na upijanje ulja i sprječavaju lijepljenje kutije za pizzu. Neki napredni dizajni čak imaju izdignute platforme ili valovite umetke koji podižu pizzu, stvarajući dodatni protok zraka ispod nje i održavajući njezinu hrskavost.

Utjecaj na očuvanje kvalitete hrane

Izvrsnost u regulaciji temperature

Održavanje optimalne temperature vjerojatno je najvažnija funkcija kutije za pizzu. Najbolje kutije stvaraju mikrookoliš koji omogućuje da pizza dugo ostane na temperaturi posluživanja. Ovo se postiže kombinacijom svojstava materijala i konstrukcijskih elemenata koji zadržavaju toplinu, a istovremeno dopuštaju suvišnoj vlazi da ispari.

Napredne kutije za pizzu često uključuju termobarijere ili reflektirajuće materijale koji poboljšavaju zadržavanje topline. Ove inovacije mogu produžiti period optimalne temperature posluživanja do 20 minuta – značajno poboljšanje koje može biti razlika između zadovoljnog kupca i hladnog, razočaravajućeg obroka.

Kontrola vlage i integritet tijesta

Borba protiv vlage stalna je pri dostavi pizze. Kutije visoke kvalitete rješavaju ovaj problem kroz pažljivo projektirane ventilacijske sustave koji održavaju delikatnu ravnotežu između zadržavanja topline i ispuštanja vlage. Time se sprječava temnjeni efekt 'znojenja' koji može pretvoriti hrskavi tijest u mokru nepriliku.

Nadređene kutije imaju specijalizirane premaze i materijale otporne na upijanje vlage, a istovremeno omogućuju odgovarajuću cirkulaciju zraka. Ovaj sofisticirani pristup upravljanju vlagom osigurava da pizze stignu s istim teksturama i kvalitetom kakvi su bili kad su napustile pećnicu.

Okolišne razmatranje i održivost

Materijali i proizvodnja prijateljski za okoliš

Proizvodnja modernih kutija za pizzu sve više se usmjerava na održivost, ne kompromitirajući pritom performanse. Vodeći proizvođači sada koriste reciklirane materijale i ekološki prihvatljive procese proizvodnje, stvarajući kutije koje su učinkovite i ekološki svjesne. Ove održive opcije često uključuju biodegradabilne materijale i minimalnu kemijsku obradu.

Utjecaj na okoliš kutija za pizzu proteže se daleko izvan njihove materijalne građe. Procesi proizvodnje koji uštedjuju energiju te optimizirani dizajni za transport smanjuju ugljični otis operacija dostave pizze. Neki inovativni proizvođači razvijaju čak i kompostabilne kutije za pizzu koje se potpuno razgrade u komercijalnim postrojenjima za kompostiranje.

Recikliranje i smanjenje otpada

Najbolje kutije za pizzu dizajnirane su s obzirom na njihov kraj životnog ciklusa. Mnoge moderne kutije lako je reciklirati, pod uvjetom da nisu jako zaprljane masnoćom i ostacima hrane. Neki proizvođači razvili su posebne tretmane koji olakšavaju odvajanje ostataka hrane od kartona, čime se poboljšava mogućnost recikliranja.

Inovativni pristupi u dizajnu smanjuju uporabu materijala, a istovremeno održavaju strukturnu čvrstoću. Uključuju opcije manje težine koje koriste manje materijala, ali pružaju istu razinu zaštite, kao i kutije dizajnirane tako da ih je lako demontirati radi recikliranja.

Ekonomski benefiti kvalitetnih kutija za pizzu

Isplativost u dugoročnim operacijama

Iako kutije za pizzu više klase imaju veću početnu cijenu, njihova superiorna izvedba često rezultira uštedom na duže staze. Bolja zaštita znači manje odbijenih dostava i smanjenje otpada od oštećenih proizvoda. Povećano zadovoljstvo kupaca vodi ka većem broju ponovnih narudžbi i pozitivnom usmenom marketingu.

Kvalitetne kutije također obično imaju dosljedniju učinkovitost, smanjujući varijable u procesu dostave i omogućujući poslovnim subjektima optimizaciju svojih operacija. Ova pouzdanost rezultira boljim upravljanjem resursima i poboljšanom profitabilnošću.

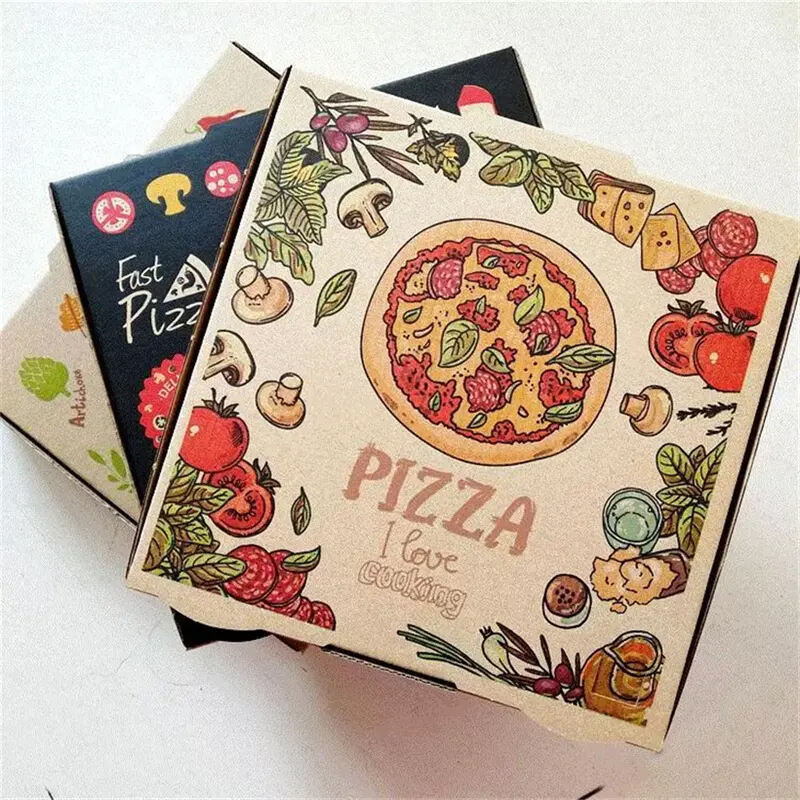

Imidž brenda i percepcija kupaca

Pizzina kutija služi kao fizički izraz posvećenosti brenda kvaliteti. Premium ambalaža šalje poruku kupcima da poslovni subjekt cijeni njihovo iskustvo i ponosi se svojim proizvodom. Ova percepcija može opravdati višu cijenu i pomoći u uspostavljanju jakog tržišnog položaja.

Mnoge uspješne pizzerije otkrile su da ulaganje u visokokvalitetne pizzine kutije donosi dividende u obliku lojalnosti kupaca i prepoznatljivosti brenda. Kutija postaje dio ukupnog gastronomskog iskustva, pridonoseći nezaboravnim trenucima koji vracaju kupce natrag.

Često postavljana pitanja

Koliko dugo kvalitetna pizzina kutija može zadržati hranu toplom?

Kutija za pizzu visoke kvalitete može održavati optimalnu temperaturu posluživanja od 30 do 45 minuta u normalnim uvjetima. Ovo razdoblje mogu utjecati čimbenici poput vanjske temperature, udaljenosti dostave i specifičnih dizajnerskih značajki kutije.

Je li svaka kutija za pizzu sigurna za hranu?

Iako su većina kutija za pizzu izrađena od materijala koji su prikladni za hranu, ne sve zadovoljavaju najviše standarde sigurnosti. Kutije visoke kvalitete koriste materijale i premaze odobrene od strane FDA-a, koji su posebno dizajnirani za izravan kontakt s hranom i izloženost toplini.

Što čini da su neke kutije za pizzu skuplje od drugih?

Premium kutije za pizzu koštaju više zbog kvalitetnijih materijala, naprednih tehničkih značajki, specijaliziranih premaza i superiornih proizvodnih procesa. Dodatni trošak obično reflektira bolju učinkovitost u zadržavanju topline, upravljanju vlagom i strukturalnoj čvrstoći.